The Challenge

The City of Palm Coast, FL, had built a water treatment facility for the future. Unfortunately, faster-than-expected growth, not unusual in Florida, had outstripped the capabilities of the facility. Palm Coast approached Harn R/O Systems to retrofit its two existing trains from 2.0 MGD to 2.4 MGD each and add two more 2.4 MGD trains. Although the plant was well built originally and well maintained, Harn R/O needed to meet the City’s future needs while meeting its current needs throughout the plant retrofit.

The Solution

Harn R/O Systems took the lead in assembling a team that incorporated contractors and subcontractors who had experience with the original plant design and construction. The City wanted people they could trust and, having dealt with similar situations on past projects, Harn knew that enlisting trusted past partners would not only make the City more comfortable but yield knowledge that would prove very valuable.

The Result

“The whole concept of design/build for these types of projects is still in an emerging phase but Harn leads the field in its knowledge and expertise.” said Brian Matthews of the City of Palm Coast. “‘They assembled the right team. They utilized the knowledge and experience of those involved in the original plant and supplemented it with their own expertise. They understood the complex needs of the project and came up with innovative solutions that were transparent in terms of our ability to deliver to our customers, especially when you’re dealing with a project of this complexity.”

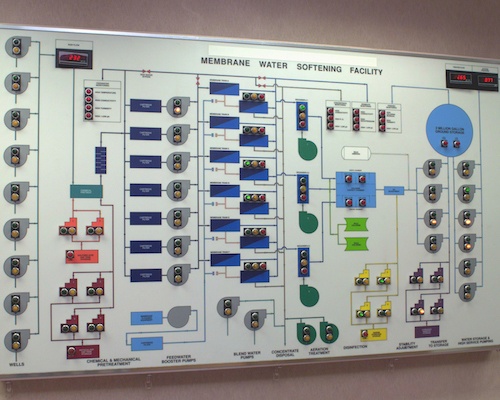

The Harn Team worked through a complicated scheduling and coordination of shutdowns throughout the retrofit to maintain capacity until the project’s completion. The close supervision and coordination of the efforts of all parties on the team is a Harn R/O trademark on these types of plant retrofits. In addition, Harn R/O was able to recommend a variety of enhancements and improvements to the plant’s treatment system such as redesigning the motor control system, and installing variable frequency drives that led to significant cost savings and greater system efficiency.

Owner:

City of Palm Coast, FL

Design Build Lead

Harn R/O Systems, Inc

Engineer:

Phase 2 – Carollo Engineers

Application:

Potable drinking water

Startup:

April 2004

Capacity:

6.4 MGD

Array:

18:9, 7-element vessels, 4 trains

Membrane:

Dow Filmtec NF90

Operating Data:

Feedwater TDS: 700 mg/l Permeate TDS: 60 mg/l R/O Feed Pressure: 100psi Recovery: 85%

System Features:

- Eliminated permeate backpressure, installed interstage boost pumps and VFD’s for energy savings and improved control

- Redesigned existing skids to improve operation and access for maintenance

- Provided turn-key system from pre-treatment through degasification